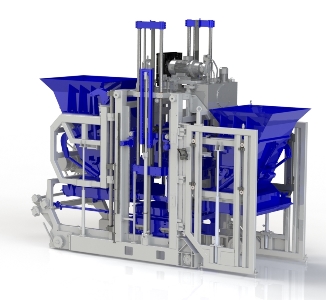

Block Making Machine Model Multimaster

This machine is ideal for a most economic mass production of paving stones, concrete bricks and other building elements. With the MULTIMASTER production and packaging are done simultaneously. Thus transport cost within the plant are reduced to an absolute minimum. Production unit = Transport unit = Stock unit.

Description of the machine

The KNAUER MULTIMASTER is powered by a combination of electro-hydraulic and motor dive units switched for simultaneous operation to achieve minimum cycle times. The distortion free and vibration-proof suspended frame construction is based on the long-time experience of KNAUER in the field of block making machine manufacturing. The heart of the machine is the vibrating system. For one the distortion free vibrating table with a synchronized medium frequency vibrator and 2 motors mounted underneath, producing directed vertical vibrations.

And secondly a high frequency overhead vibrator mounted on the ram. (Image 2)

Basically the vibrator of the table and ram are the same type, but the frequency and centrifugal force setup of the 2 vibrators is different. The combination of different frequencies of the vibrating table vibrator and the ram vibrator gives the best results to achieve the highest possible compaction. (Image 3)

Production sequence

The sequence of operation is automatically controlled. All individual functions of the machine can also be operated manually. Uses is made of the manual controls to determine the optimum values for all different functions of the machine, which can then be fed into the automatic program control. By pushing the AUTOMATIC button, fully automatic production is initiated and one operator is sufficient to supervise and feed the machine.

Decision making factors

The productivity and profitability of a concrete block plant depends on the choice of the right machinery. Here are some decisive factors:

- Space requirements:

A track length of 110 m is required for an 8 hour production of paving stones. The machine is fed either by mono rail, a trilateral concrete loader or a forklift truck with a hopper.

- 2. Cycle times:

Cycle time fluctuate between 25 and 35 sec. per cycle of paving stones , depending on the composition and structure of the raw material available and approx. 35-45 sec. per cycle when face mix (a second layer of fine concrete) is added.

- 3. Output per day:

Following a list of expected daily output for different products per 8 h shift. Assumed is a constant material feed and no downtime.

| Type of block | Dimensions | Per cycle | Per 8 h | Track length |

| Paving Stone | 200x100x60 mm | 1,08 m² | 800 m² | 110 m |

| Hollow block | 200x400x200 mm | 12 | 9840 pcs. | 250 m |

| Curb stones | 1000x150x250 mm | 6 | 3840 pcs. | 800 m |

| Technical Data: | |

Usable mould dimensions |

|

![[Translate to Englisch:] Ansprechpartner](/assets/content/dummy-ansprechpartner.png)

Contact person

For questions about the product range "Block Making Machines", please contact

Peter Ortmann

08171 - 6295-24

E-Mail

![[Translate to Englisch:] Multimaster](/assets/produkte/pdf/prospekt_multimaster.jpg)